We take your privacy very seriously and when you visit our website, please agree to all cookies used.

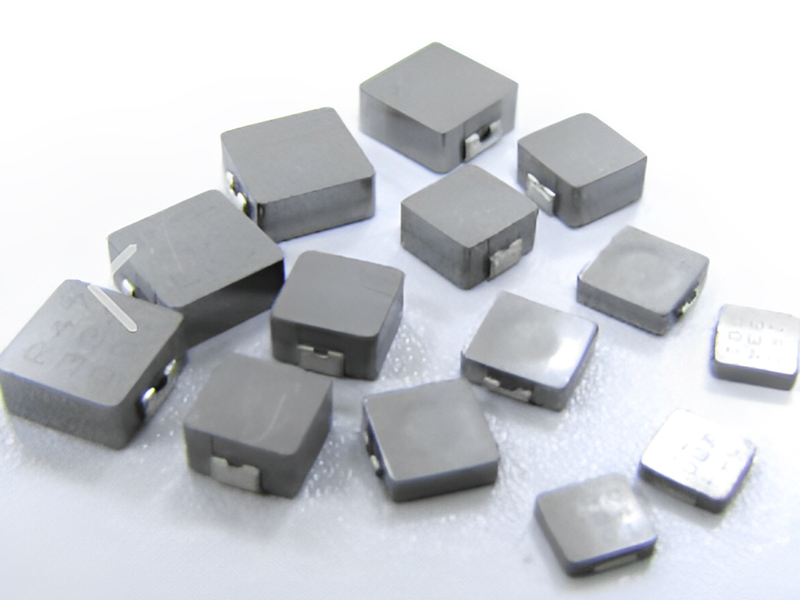

Molded inductor structure is different from other types of magnetic devices. Molded inductors are manufactured by compressing a magnetic material in a mold using an adhesive or polymer, and compressing the magnetic material around a conductive air coil to form an integrated structure. The magnetic material used in this process is a soft magnetic atomized powder. The compressed structure is cured in an oven to form a solid composite structure. The use of adhesives/polymer materials serves to distribute the gaps and thus enhance the magnetic properties. The binder/polymer composition used in the product encapsulates the composite materials' powder, which helps to block the part from becoming magnetic and prevents the part from oxidizing in a humid environment.